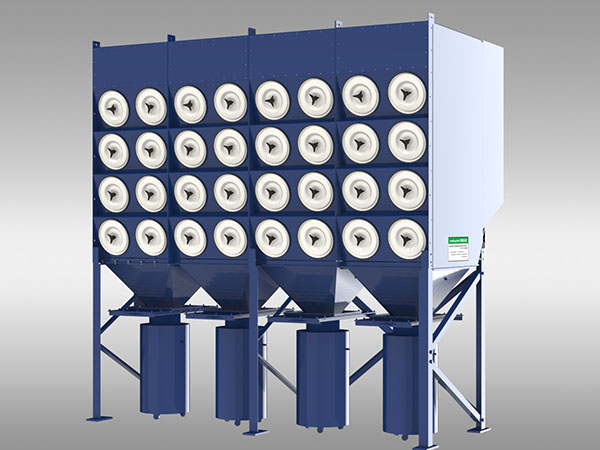

I-Cartridge Dust Collector

Incazelo emfushane:

Isakhiwo sekhatriji yesihlungi esime mpo sisetshenziselwa ukwenza lula ukumuncwa kothuli nokususwa kothuli; futhi ngenxa yokuthi impahla yokuhlunga inyakaza kancane ngesikhathi sokususwa kothuli, impilo ye-cartridge yesihlungi yinde kakhulu kunaleyo yesikhwama sokuhlunga, futhi izindleko zokunakekela ziphansi.

Uhlolojikelele

Umqoqi wothuli wohlobo lwe-cartridge ubizwa nangokuthi umqoqi wothuli wohlobo lwemagazini noma umqoqi wothuli wohlobo lwe-cartridge. Izici eziyinhloko yilezi ezilandelayo:

1.Isakhiwo sekhatriji yesihlungi esime mpo sisetshenziselwa ukwenza lula ukumuncwa kothuli nokususwa kothuli; futhi ngenxa yokuthi impahla yokuhlunga inyakaza kancane ngesikhathi sokususwa kothuli, impilo ye-cartridge yesihlungi yinde kakhulu kunaleyo yesikhwama sokuhlunga, futhi izindleko zokunakekela ziphansi.

2.Ukwamukela indlela yamanje yamazwe ngamazwe yokuhlanza engaxhunyiwe ku-inthanethi ethuthukisiwe yezifunda ezintathu (ukuhlunga, ukuhlanza, i-static) ukugwema into "yokuphinda i-adsorption" ngesikhathi sokuhlanza, okwenza ukuhlanza kuthembeke ngokuphelele.

3.Idizayinelwe ngendlela yokuqoqa uthuli lwangaphambi kothuli, olungagcini nje ngokunqoba ukushiyeka kokukhuhla uthuli oluqondile futhi kulula ukugqoka i-cartridge yokuhlunga, kodwa futhi ingakhuphula kakhulu ukugxilwa kothuli emnyango womqoqi wothuli.

4. Izingxenye ezingenisiwe zisetshenziselwa izingxenye ezibalulekile ezithinta ukusebenza okuyinhloko (njenge-valve ye-pulse), futhi impilo yesevisi ye-diaphragm yengxenye esengozini idlula izikhathi eziyizigidi ezingu-1.

5. Ukwamukela ubuchwepheshe obuhlukene bokufafaza nokuhlanza, i-valve eyodwa ye-pulse ingafafaza umugqa owodwa ngesikhathi esifanayo (inani lama-cartridges okuhlunga emgqeni ngamunye lifika ku-12), elinganciphisa kakhulu inani lama-valve e-pulse.

6. Umshini wokuhlanza umlotha wezifunda ezintathu we-valve ye-pulse wamukela ukulawula okuzenzakalelayo kwe-PLC, futhi unezindlela ezimbili zokulawula, isikhathi noma imanuwali, ongakhetha kuzo.

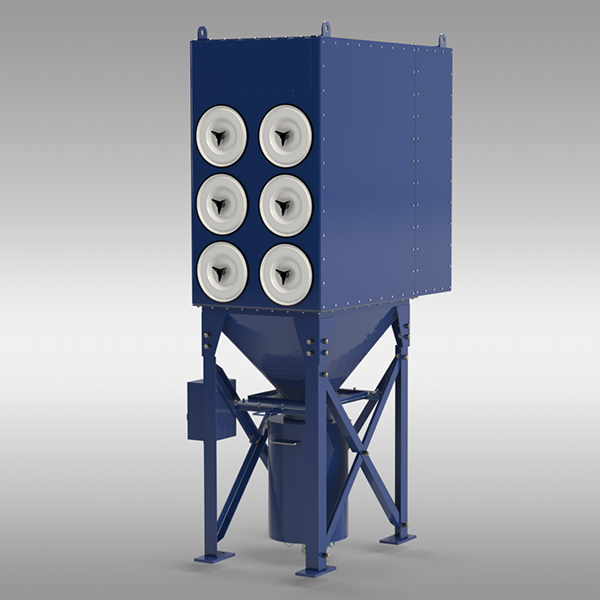

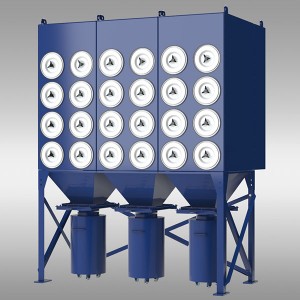

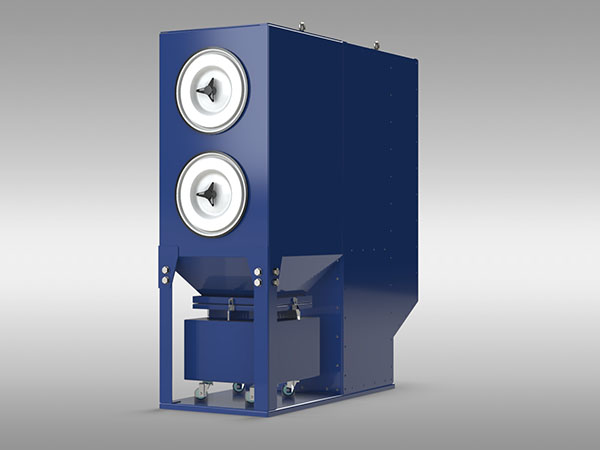

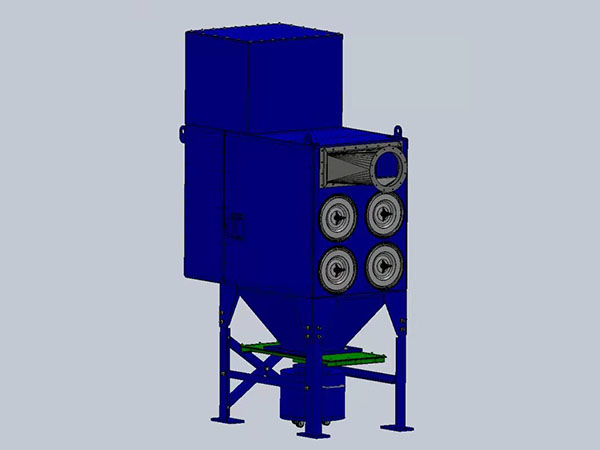

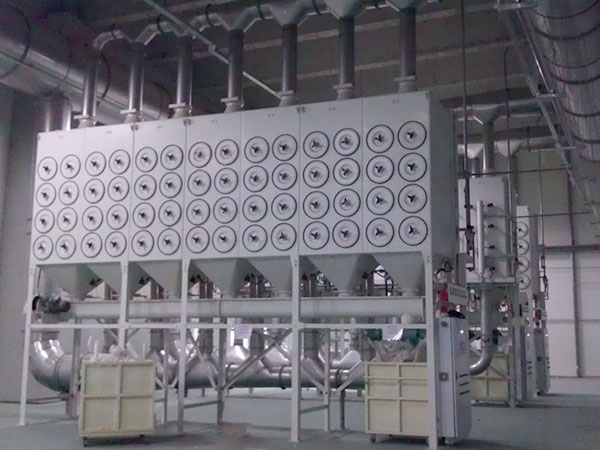

7. Noma iyiphi inhlanganisela yama-cartridges okuhlunga anezinombolo ezahlukene zamakholomu nemigqa ingasetshenziswa ngokuvumelana nezidingo zesikhala sokufaka; isikhala esinezinhlangothi ezintathu esithathwe indawo yesihlungi seyunithi sincane, esingagcina izinsiza eziningi zesikhala somsebenzisi futhi sinciphise ngokungaqondile izindleko zokutshala zesikhathi esisodwa zomsebenzisi.

8.Impilo ende yesevisi, impilo yesevisi ye-cartridge yesihlungi ingafinyelela eminyakeni emi-2 kuya kwemi-3, okunciphisa kakhulu inani lezikhathi lapho ingxenye yesihlungi somqoqi wothuli ishintshwa (isihlungi sesikhwama sendabuko sishintshwa njalo ngezinyanga eziyi-6 ngokwesilinganiso), ukugcinwa ilula, futhi nokugcinwa kuyancipha kakhulu. Izindleko zokulungisa zomsebenzisi ngesikhathi sokusetshenziswa.

9.Lo mkhiqizo usetshenziselwa kakhulu uthuli lwezimboni ku-iron nensimbi yensimbi, ukuncibilika okungeyona insimbi, usimende wokwakha, ukubunjwa kwemishini, imboni yokudla kanye nokukhanya, imboni yamakhemikhali yansuku zonke, ugwayi, amadokhu okugcina, ama-boilers eziteshini zamandla ezimboni, ama-boilers okushisa, kanye nemfucuza kamasipala. izimboni zokushiswa kwempahla. Ukuhlanzwa kanye nokubusa.

Isakhiwo

Umqoqi wothuli wohlobo lwe-cartridge wakhiwe ipayipi lokungenisa umoya, ipayipi lokukhipha umoya, umzimba webhokisi, i-ash hopper, idivayisi yokuhlanza umlotha, idivayisi yokuphambukisa, ipuleti lokusabalalisa ukugeleza komoya, i-cartridge yesihlungi kanye nedivayisi yokulawula kagesi, efana ne-air box pulse bag ukususwa kothuli. Ukuhlelwa kwe-cartridge yokuhlunga ekuqoqweni kothuli kubaluleke kakhulu. Ingahlelwa ngokuqondile ophahleni lwekhabhinethi noma ithambekele phezulu. Ngokombono womphumela wokuhlanza, ukuhlelwa okuqondile kunengqondo. Ingxenye engezansi yophahla iyigumbi lokuhlunga, futhi ingxenye engaphezulu yi-air box pulse chamber. Ipuleti lokusabalalisa umoya lifakwa emnyango womqoqi wothuli.

Isimiso Sokusebenza

Ngemuva kokuthi igesi equkethe uthuli ingene endaweni yokubeka uthuli lomqoqi wothuli, ngenxa yokwanda okungazelelwe kwesigaba esiphambanayo sokugeleza komoya kanye nomthelela wepuleti lokusabalalisa komoya, ingxenye yezinhlayiya ezimahhadla ekugelezeni komoya zihlala emlotheni. i-hopper ngaphansi kwesenzo samandla ashukumisayo kanye ne-inertial; izinhlayiya zothuli ezinohlamvu oluncane neziphansi zingena ekamelweni lokuhlunga uthuli. Ngemiphumela ehlanganisiwe yokusabalaliswa kwe-Brownian nokusefa, uthuli lufakwa phezu kwendawo yokuhlunga, futhi igesi ehlanziwe ingena ekamelweni elihlanzekile lomoya futhi likhishwa ipayipi lokukhipha umoya ngefeni. Ukumelana nesihlungi se-cartridge kuyanda ngokwanda kogqinsi lwengqimba yothuli ebusweni bento yokuhlunga. Hlanza uthuli lapho ukumelana kufinyelela inani elithile elicacisiwe. Ngalesi sikhathi, uhlelo lwe-PLC lulawula ukuvulwa nokuvalwa kwe-valve ye-pulse. Okokuqala, i-valve yokuphakamisa i-sub-chamber ivaliwe ukuze kunqandwe ukugeleza komoya okuhlungiwe, bese kuvulwa i-electromagnetic pulse valve. Umoya ocindezelwe kanye nesikhathi esifushane kunwetshwa ngokushesha ebhokisini eliphezulu futhi kuthululwe ku-cartridge yesihlungi ukwenza i-cartridge yokuhlunga Ukwandiswa nokuguqulwa kukhiqiza ukudlidliza, futhi ngaphansi kwesenzo sokugeleza komoya okuphambene, uthuli oluxhunywe ngaphandle. ubuso besikhwama sokuhlunga buhlutshiwe futhi buwele ku-ash hopper. Ngemva kokuqedwa kokususwa kothuli, i-valve ye-electromagnetic pulse ivaliwe, i-poppet valve iyavulwa, futhi igumbi libuyela esimweni sokuhlunga. Ukuhlanza kwenziwa ekamelweni ngalinye ngokulandelana, futhi umjikelezo wokuhlanza uqala kusukela ekuhlanzweni kwekamelo lokuqala kuya ekuqaleni kokuhlanza okulandelayo. Uthuli oluwile luwela ku-ash hopper futhi lukhishwe ngevalve yokukhipha umlotha.

Inqubo yokukhipha uthuli yeqoqo le-cartridge ye-cartridge yokuqoqa uthuli iwukuba kuqala unqamule ishaneli yokukhipha umoya ehlanzekile yekamelo elithile, wenze igumbi libe sesimweni esimile, bese wenza i-air pulse back-blowing ukuze uhlanze uthuli, bese kuba imizuzwana embalwa ngemva kokususwa kothuli Ngemva kokuhlala kwemvelo, umzila wokukhipha umoya ohlanzekile wekamelo uphinde uvulwe, ongagcini nje ngokuhlanza uthuli ngokuphelele, kodwa futhi ugwema ukukhangiswa kwesibili kothuli olukhiqizwa ukufutha futhi. ukuhlanza, ukuze uthuli lusakazwe kusuka ekamelweni kuya kwelinye.

Ukukhethwa komqoqi wothuli

1. Ukunqunywa kwesivinini somoya wokuhlunga

Ukuhlunga isivinini somoya kungenye yemingcele ebalulekile yokukhethwa kwabaqoqi bothuli. Kufanele kunqunywe ngokuya ngemvelo, usayizi wezinhlayiyana, izinga lokushisa, ukugxila kanye nezinye izici zothuli noma intuthu ekusetshenzisweni okuhlukene. Ngokuvamile, uthuli olungena ngaphakathi luyi-15-30g/m3. Isivinini somoya wokuhlunga akufanele sibe ngaphezu kuka-0.6~0.8m/min; ukugxiliswa kothuli lwe-inlet kufanele kube ngu-5~15g/m3, futhi isivinini somoya wokuhlunga akufanele sibe ngaphezu kuka-0.8~1.2m/min; ukugxila kothuli olungenayo kufanele kube ngaphansi noma kulingane no-5g/m3, futhi isivinini somoya sokuhlunga akufanele sibe Ngaphezu kuka-1.5~2m/min. Ngamafuphi, lapho ukhetha isivinini somoya sokuhlunga, ukuze unciphise ukumelana kwemishini, ngokuvamile isivinini somoya sokuhlunga akufanele sikhethwe sibe sikhulu kakhulu.

2. Hlunga impahla

Isihlungi se-cartridge se-JWST samukela i-PS noma i-PSU polymer coated fiber filter material. Uma igesi ehlungiwe ikwizinga lokushisa elilingana negumbi noma ngaphansi kuka-100°C, i-PS polymer coated fiber filter material ngokuvamile isetshenziswa. Uma isetshenziswa ekusetshenzisweni kokushisa okuphezulu, kufanele isetshenziswe. I-PSU polymer coated fiber filter material, uma isetshenziswa ngezikhathi ezinezidingo ezikhethekile, kufanele ishiwo ngaphambi koku-oda, futhi okokuhlunga kufanele kukhethwe ngokwehlukana.

3.Ifomu lokukhipha umlotha

Abaqoqi bothuli be-cartridge filter yochungechunge lwe-JWST bonke basebenzisa ama-screw conveyors ukuze bakhiphe umlotha (abaqoqi bothuli bemigqa 1-5 basebenzisa izinto ezikhipha inkanyezi ukukhipha umlotha).

Isistimu yokutakula ingxenye yesihlungi iyifeni elidonsa umoya oqukethe impushana, liwuhlunge ngesihlungi somoya, bese lisebenzisa i-pulse circuit ukulawula okuzenzakalelayo. Impushana ekhangiswe endaweni yesihlungi somoya ngesikhathi sokufuthwa kwempushana izoba Yehlisela phansi ngokugeleza komoya onomfutho ophezulu.

Imodeli yomkhiqizo

I-JT-LT-4

I-JT-LT-8

I-JT-LT-12

I-JT-LT-18

I-JT-LT-24

I-JT-LT-32

I-JT-LT-36

I-JT-LT-48

I-JT-LT-60

I-JT-LT-64

I-JT-LT-112

I-JT-LT-160