I-One Unit Dust Collector Kanye Nefeni Nezimoto

Incazelo emfushane:

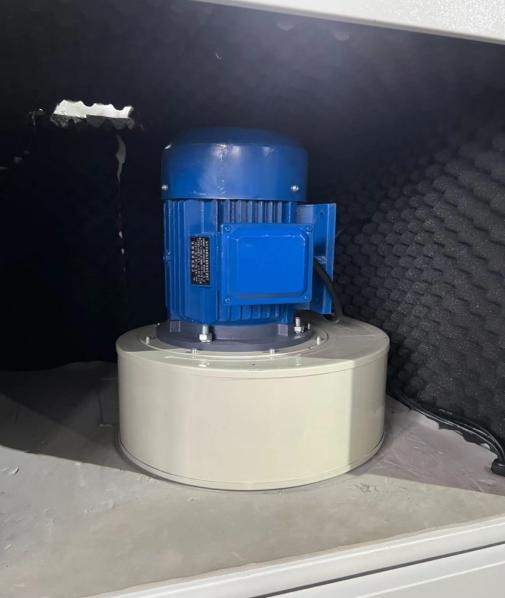

Ngamandla adonsela phansi efeni, uthuli lwentuthu yokushisela lumuncwa entweni esetshenziswayo ngepayipi lokuqoqa, bese lungena egunjini lokuhlunga. Isibambisi somlilo sifakwa endaweni yokungena egunjini lesihlungi, esihluza izinhlansi othulini lwentuthu yokushisela, sinikeze ukuvikeleka okukabili kwesilinda sokuhlunga. Uthuli lwentuthu yokushisela lugeleza ngaphakathi kwegumbi lokuhlunga, lisebenzisa amandla adonsela phansi kanye nokugeleza komoya phezulu ukuze lwehlise ngokuqondile uthuli olumahhadla lwentuthu ekhabetheni lokuqoqa umlotha. Intuthu yokushisela equkethe uthuli oluyizicucu ivinjwa isilinda sokuhlunga esiyicylindrical, Ngaphansi kwesenzo sokuhlola, uthuli lwezinhlayiya luvaleleke phezu kwekhatriji yesihlungi. Ngemva kokuhlungwa nokuhlanzwa ngekhatriji yesihlungi, intuthu yokushisela kanye negesi ephumayo igeleza ingene egumbini elihlanzekile isuka maphakathi nekhatriji yesihlungi. Igesi elisegunjini elihlanzekile libe selikhishwa endaweni yokukhipha izinto zokusebenza ngemva kokudlulisa izinga ngesiphepho esifakiwe.

Isimiso Sokusebenza

Ngamandla adonsela phansi efeni, uthuli lwentuthu yokushisela lumuncwa entweni esetshenziswayo ngepayipi lokuqoqa, bese lungena egunjini lokuhlunga. Isibambisi somlilo sifakwa endaweni yokungena egunjini lesihlungi, esihluza izinhlansi othulini lwentuthu yokushisela, sinikeze ukuvikeleka okukabili kwesilinda sokuhlunga. Uthuli lwentuthu yokushisela lugeleza ngaphakathi kwegumbi lokuhlunga, lisebenzisa amandla adonsela phansi kanye nokugeleza komoya phezulu ukuze lwehlise ngokuqondile uthuli olumahhadla lwentuthu ekhabetheni lokuqoqa umlotha. Intuthu yokushisela equkethe uthuli oluyizicucu ivinjwa isilinda sokuhlunga esiyicylindrical, Ngaphansi kwesenzo sokuhlola, uthuli lwezinhlayiya luvaleleke phezu kwekhatriji yesihlungi. Ngemva kokuhlungwa nokuhlanzwa ngekhatriji yesihlungi, intuthu yokushisela kanye negesi ephumayo igeleza ingene egumbini elihlanzekile isuka maphakathi nekhatriji yesihlungi. Igesi elisegunjini elihlanzekile libe selikhishwa endaweni yokukhipha izinto zokusebenza ngemva kokudlulisa izinga ngesiphepho esifakiwe.

Njengoba ukushuba kongqimba lothuli ebusweni bekhatriji yesihlungi kukhula, ikhono le-cartridge yesihlungi ukuhlunga nokuhlanza umoya lizokwehla, futhi ukwehla kwengcindezi yokugeleza komoya ongenayo nokuphumayo kuzokhuphuka, okuzoholela ekutheni ukwehla ekusebenzeni kahle kokuhlanza. Ukuze ugweme izinguquko ezibalulekile ekucindezelweni kokuhlunga kwemishini, uhlelo lokuvuthela okuphambene nokuhlanza lwemishini lusebenza kanyekanye nohlelo lokuhlunga. Ithuluzi lokulawula ukushaya kwenhliziyo lilawula ukuvulwa kwevalvu ye-electromagnetic pulse ngayinye ngokuya ngobubanzi obusethiwe beshayela kanye nokulandelana kwesikhawu sokushaya kwenhliziyo. Umoya ocindezelwe osesikhwameni somoya udlula ku-valve ye-pulse ngembobo evuthelayo epayipini eliphephethayo, ukhiphe ukugeleza komoya wejethi onesivinini esikhulu nomfutho ophezulu, okubangela ukugeleza komoya okubangelwe okuphindwe izikhathi eziningana kunomthamo womoya we-jet faka i-cartridge yesihlungi, ingcindezi esheshayo evelayo iyenzeka ngaphakathi kwe-cartridge yesihlungi, ibangele ukuthi i-cartridge ikhule, okubangela ukuthi uthuli olufakwe ku-cartridge luwohloke futhi luqhekeke, luhlukanise. ngamabhuloki asuka ku-cartridge. Lokhu kubuyisela ngokulandelana ikhono le-cartridge lokuhlunga nokuhlanza umoya esimweni salo sokuqala, kunciphisa ukushaya ngamandla kokumelana komoya, ukugcina ukwehla kokucindezela okulinganiselwe kanye nokusebenza kahle kokuhlunga okuzinzile. Uthuli oluphuma ebusweni be-cartridge yokuhlunga luwela ebhakedeni lokuqoqa umlotha, futhi uthuli ebhakedeni lokuqoqa umlotha lungahlanzwa njalo ngokuvumelana nezimo zokusebenza.

Izici zezisetshenziswa

1. Izinto zokuhlunga ziyingxenye ebalulekile yokuqoqa uthuli lokuhlunga kanye nenhliziyo yemishini yokususa uthuli. Ukusebenza kwayo nekhwalithi kubalulekile empilweni yesevisi kanye nokusebenza kokukhishwa kwentuthu kwesisetshenziswa. Amakhatriji okuhlunga asetshenziselwa ukushisela intuthu nesihlanzi sothuli akhiqizwe yinkampani yethu wonke enziwe ngezinto ezingeniswa kwamanye amazwe ze-PTFE polyester fiber. Lesi sici sine-coefficient ephansi kakhulu yokungqubuzana, ukumelana kahle nokugqokwa, kanye nokuzinza okuhle kakhulu kwamakhemikhali, ukunemba okuphezulu, nomthelela omuhle wokuhlunga. Ngokwezimo zokusebenza, ukucwiliswa okuphezulu kungafinyelela kuma-micrometer angu-0.2, futhi ukusebenza kahle kokuhlanza kungu-99.99%. Ingaphezulu lale nto libushelelezi ngokwedlulele futhi akulula ukunamathela, okwenza kube lula ukuhlanza i-pulse back blow. Impilo yesevisi ye-cartridge yokuhlunga yinde kakhulu, futhi ingafinyelela iminyaka engu-2-3 ngaphansi kwezimo ezijwayelekile zokusebenza.

2. I-dust baffle ifakwe endaweni yokufaka uthuli yesiqoqi sothuli se-cartridge yesihlungi esisebenza kahle kakhulu, esinomphumela wokubhafa nokumelana nokuguga futhi ngeke kube nomthelela oqondile ku-cartridge yesihlungi ngesivinini esikhulu, ngaleyo ndlela andise impilo yesevisi yesihlungi. i-cartridge.

3. Indlela yokuhlanza umlotha: Umqoqi wothuli we-cartridge wesihlungi osebenza kahle kakhulu wamukela ukuhlanzwa komlotha okuzenzakalelayo kwe-pulse jet, okusho ukuthi ama-cartridge okuhlunga ahlanzwa ngokuzenzakalelayo ngokulandelana ngakunye. I-valve ye-pulse ivulwa kanye ukuze kukhiqizwe isenzo se-pulse, futhi ukuqina kanye nemvamisa ye-pulse jet kungalungiswa. Umphumela wokuhlanza umlotha muhle, futhi ukuhlanza nokuhlunga akuthinti omunye nomunye, ukuqinisekisa ukuthi okokusebenza kuhlala kusesimweni esihle sokusebenza futhi kuthuthukisa ukusebenza kahle kokukhiqiza.

4. Ukusebenza okusebenzisekayo komqoqi wothuli we-cartridge yesihlungi esisebenza kahle kakhulu kuzinzile, futhi ukushintshwa kulula futhi kuyashesha.